Building Engineering Services

This page or section needs to be cleaned up. |

Please help to expand this page. |

POLICY AND SERVICE CONTEXT

Overview

Many of the Building Engineering Services of a health facility have specialised needs within the context of healthcare provision and infection prevention and control. Specialist needs may include a combination of hygiene, redundancy and contamination-control requirements over and above the normal best engineering practice.

The Building Engineering Services dealt with in this document include: ventilation systems, wet services, gas and vacuum services, electrical services and electronic services. The primary function of this document is to provide terms of reference to designers who are contacted to develop building engineering services systems. This document does not serve as a principal facility planning guide but as a best-practice guide within any planned level of healthcare service.

“This document describes engineering design, installation and commissioning principles in terms of current specialist clinical, contamination control and maintenance requirements“

Policy and Service Context

Context

This document serves as guidance in the development of all levels of the healthcare facility. Certain sections may not be applicable to all considered levels of facility although, where a certain engineering service is supplied, that service shall be developed in accordance with the guiding principles contained herein.

Design principles

This document will detail design principles within the scope of services described in the Engineering Council of South Africa’s gazetted Guideline scope of services and tariff of fees in terms of the Engineering Professions Act (46 of 200). This document will also describe design, installation and commissioning principles in terms of current specialist clinical, contamination-control and maintenance requirements. While this document details design requirements and acceptance criteria which have an impact on clinical services, these requirements are prescribed within the framework of the entire IUSS set of guidance documents, and cannot be viewed in isolation. The following documents should be complied with, together with this document:

Within the South African healthcare context, many clinical and administrative zones may be subject to infection prevention and control measures with particular consideration for airborne contamination control.

| Clinical services | Essential | Recommended | Support Services | Essential | Recommended | Healthcare environment/

Crosscutting issues |

Essential | Recommended | Procurement &

Operation |

Essential | Recommended |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Impatient services | X | Administration & related services | Generic room data | X | Integrated infrastructure planning | X | |||||

| Laboratories | X | General hospital support services | Hospital design principles | X | Project planning & briefing | X | |||||

| Mental Health Services | Catering services | Engineering design principles | X | Space guidelines | |||||||

| Critical care | Laundry and Linen | Environment and sustainability | X | Cost Guidelines | X | ||||||

| Emergency centres | Mortuary | X | Materials & finishes | X | Procurement liaison | ||||||

| Obstetrics & gynaecology | Nursing colleges | Future healthcare environments | X | Commissioning | X | ||||||

| Oncology | Health facility residential | Healthcare technology | Maintenance | X | |||||||

| Outpatient services | X | Sterile supply | X | Inclusive environments | X | Decommissioning | X | ||||

| Paediatrics | Clinical training | Infection prevention & control | X | Capacity development | X | ||||||

| Pharmacy | Waste disposal | X | Health informatix | ||||||||

| Primary health care | Regulations | X | |||||||||

| Diagnostic radiology | X | ||||||||||

| Rehabilitation services | |||||||||||

| Sub-acute services | |||||||||||

| Surgery | X | ||||||||||

| TB | X |

Where this document lacks guidance on a topic or appears to contradict the requirements of the guidelines identified above, the guidance of those documents will take priority.

Service Context

Levels of care

- “Levels of Care” is discussed in detail in the Project Planning and Briefing document. The Building Engineering Services document does not prescribe levels of care within the healthcare system and does not delineate the application of technology within these levels. It intends only to describe the building engineering services and technical aspects that should be considered from the concept development to the closeout and handover stages of the project. It is not incumbent on the engineer to prescribe appropriate levels of care and this subject is therefore not addressed herein. The allocation of appropriate technologies and services within the prescribed levels of care is a function of the engineer during the facility-planning stage as described by this document.

- In this document, where three distinct options are made describing system quantities or capacities, these are to be interpreted as the minimum acceptable standard, recommended best practice, and maximum practical limit respectively. Where only two options are given, these are to be interpreted as the minimum standard and best practice respectively. Where only one option is given, this is to be interpreted as the minimum acceptable standard. The reader is cautioned not to interpret these capacity standards as levels of care.

-

King George V (KZN 2013)

PLANNING AND DESIGN

Overview

The national and provincial service and policy context should be the basic determinant of planning and design principles in the public sector

The national and provincial service and policy context (Part A of this document) is the basic determinant of planning and design principles in the public sector. In the private sector, planning and design will have determinants as defined by the service provider, within certain minimum prescribed limits. Part B describes the scope of planning and design guidance, design considerations and functional relationships between engineering systems. These principles are subsequently developed into a series of Design Specifications (Part C), Commissioning, Handover and Decommissioning (Part D) including some case studies (Part E). Parts C, D and E are intended to demonstrate how the principles prescribed in Part B should be applied. Parts C and D, if used directly, are deemed to satisfy the principles developed in Part B, but are not the only acceptable solutions. Case studies (Part E) are for illustrative purposes, to demonstrate worked solutions and should not be adopted without appropriate contextual adaptation

Stages of design and implementation

- It is critical that building engineering services professionals involve themselves in the early stages of a project’s initial planning, studies, investigations and assessments. Exclusion or late inclusion of an engineering team from the planning stages of a multi-disciplinary construction project presents a considerable risk of resulting, not in savings, but fruitless expenditure, design delays and ultimately compromises in the functional and build quality of the product.

- The scoping and broad coordination of services is invaluable during concept development, and the value-added through the early inclusion of building services professionals is frequently underestimated.

- Briefing authorities or developers are therefore encouraged to ensure that the client’s representative consults with a team of engineering professionals during the earliest project-planning stages. The deliverables of the concept and viability study stages should, therefore, include the following:

- Summaries of collated information

- Reports on technical feasibility, benefits and risks

- Reports on regulatory compliance issues

- Reports on financial feasibility and risks

- List of consents and approvals required

- Schedule of additional surveys, tests, analyses, studies and investigations.

- The Guideline Scope of Services and Tariff of Fees for Persons Registered in Terms of the Engineering Profession Act 46 of 2000 (2012) defines the following as within the Normal Scope of Professional Services.

- INCEPTION

- At the inception stage, the client’s requirements and needs are established. The project brief is established and the professional team is appointed. The professional team should contribute towards developing the project brief and concluding the terms of its appointment. Here the professional team should advise on criteria that could significantly impact on the project life cycle cost.

- CONCEPT AND VIABILITY STUDY

- At the Concept and Viability study stage, the preliminary design details and cost estimates should be finalised. This should be concluded in accordance with the project brief.

- A Preliminary design report would include the:

- Concept design

- Process design

- Schedule of design assumptions, required surveys, tests, reports and investigations

- Preliminary design details

- Installation and life cycle cost estimates

- DESIGN DEVELOPMENT / DETAIL DESIGN

- During design development the design team will further develop the concept to realise the following:

- Finalised design

- Detail specification outline

- Financial plan

- Project programme.

- During design development the design team will further develop the concept to realise the following:

- DOCUMENTATION AND PROCUREMENT

- This stage is often combined with the design development stage.

- Its deliverables include:

- Procurement and construction documentation and specifications

- Application of timeous procurement strategies appropriate for the project

- Assisting in the tender evaluation of detailed services and samples for compliance with the design intent.

- CONTRACT ADMINISTRATION AND INSPECTION

- This stage includes the management and administration of the construction contracts and works to facilitate practical completion in accordance with the design intent.

- CLOSEOUT

- Closeout deliverables include:

- Final works-completion lists

- Financial reports and final accounts

- Facilitation in development of Operation and Maintenance Manuals (O&Ms), warranties and guarantees.

- As-built drawings

- Closeout deliverables include:

- INCEPTION

Design Questions

6. In order for the engineer to satisfactorily fulfil the user’s requirements, the following list of questions should be asked, answered and understood by the professional services team.

“Engineers responsible for the design of environmental control systems require guidelines and standards, in order to derive at and to specify appropriate solutions to the problem of building related illness (BRI) in occupied spaces.” -Dr S. A Parsons 2002

- Is the building service required, and why?

- What options are available?

- What is the service’s required performance?

- What is the service’s expected lifespan?

- What is needed in terms of energy management?

- What are the expected service consumption rates?

- What are the expected occupancy profiles per planning unit, considering:

- Patient and staff numbers?

- Peak occupancy times?

- Airborne infection risk profile?

- Seasonal occupancy profiles?

- What are service distribution constraints, considering:

- Location

- Space?

- Fire protection and regulations?

- Services coordination?

- Access for maintenance and operations?

- Repair replacement and refurbishment?

- What are the minimum component/system requirements?

- What are the specific requirements regarding functional controls?

- What are validation and testing requirements

- What are the Maintenance and operational requirements?

- Commissioning and handover requirements

- Special requirements for test and balance documents and certificates

Design considerations

7. Deep buildings

- Deep buildings inevitably result in some measure of ventilation being required within the core areas. Where deep buildings cannot be avoided, the extent of building ventilation can be minimised by planning the deep-core areas as those that require specialist ventilation systems and which could not be served by natural ventilation.

8. Plant and plant room size and location

- Noisy and vibrating equipment shall not be placed near, above or below sensitive areas such as operating rooms and ICUs. They shall be designed and located so as to give sufficient reduction in noise and vibration.

- Plant rooms shall be designed such that there is safe access to equipment for maintenance and repair activities. Plant rooms shall be located away from possible heat and contamination sources.

- Plant rooms shall be located in an accessible area which is secured from unauthorized entry

- Where plant room equipment presents a potential source of airborne contamination (e.g. Legionella and vacuum exhaust) the location of the plant room shall be such that contaminated air is not carried into occupied spaces and air inlets.

Life cycle cost determination

9. When planning and designing building engineering services, the engineer shall take cognisance of the service context within which the facility is placed. As part of the financial plan, outlined in the concept and viability study stage, the engineer will assist in developing the facility’s life cycle cost by giving input into the life cycle cost estimates for the services within the engineer’s responsibility. This financial plan shall be finalised as a deliverable of the detail design stage.

10. Environmental life cycle planning is a critical element of the life cycle planning but should be considered as a service additional to the scope of the normal prescribed services.

Site-survey requirements

11. In order for the engineer to plan adequately, a detailed site survey will need to be conducted to present essential planning information. These factors need to be weighed against the level of service to be provided.

The National Department of Public Works has developed a comprehensive site-survey model for the completion of this task (Citation needed). The following list summarises the information that needs to be developed.

- Geotechnical considerations

- Availability, quantity and quality of mobile phone reception

- Availability, quantity and quality of services such as:

- Electricity

- Water supply

- Drainage conditions

- Gas

- Land and air transport

- Outsourced laundry and catering services

- Proximity to additional social services

Maintenance Considerations

12. Maintenance failures within the building services of the healthcare environment have the potential for severe consequences. Services should be designed with this in mind.

13. The design should consider the financial and environmental impact of disposable and reusable components within the planned maintenance regime. Reporting on the financial aspects of the life cycle plan is required within the normal scope of services of the planning and design project stages.

14. In the development of healthcare building engineering services the designer should consider the following maintenance challenges when designing systems and planning maintenance regimes:

- Where highly specialised services are installed in remote areas, it becomes difficult to source the requisite level of technical skills and, as a result, either maintenance costs rise or the serviceable life of these systems is decreased.

- The availability of spares and contracted technical services becomes problematic in remote locations and this leads to difficulties with unscheduled maintenance and extended callout response times.

- Routine and unscheduled maintenance may need to be performed with a system in operation, with minimal down-time. This should be considered when planning levels of redundancy.

- Routine and unscheduled maintenance should not have a negative impact of the service levels of healthcare. Where IPC and cross-infection risks are high, systems should be designed such that the maintenance staff can complete their work without affecting staff or patient safety.

15. For further guidance on health-facility maintenance, the IUSS Health Facilities Maintenance guidance document should be referred to.

Planning for Retrofitting & Decommissioning

16. While engineering systems may have a functional life of 20 to 25 years, healthcare buildings could have a life of 50 years. It is therefore likely that engineering services would need to be decommissioned, retrofitted, and replaced at least once during the life of a building, and these interventions should be planned for.

17. Projects with a retrofitting element shall include for the formal decommissioning of equipment or services which become redundant or obsolete as a result of the retrofitting project or can be conveniently decommissioned within the project. Decommissioning of any assets shall be undertaken in accordance with the Public Finance Management Act 1 of 1999, the Generally Accepted Accounting Practice, the Companies Act of 2006 and principles of good corporate governance.

18. When planning for retrofitting and decommissioning, consideration should be given to the following aspects:

- Development and implementation of a risk assessment and hazard control plan.

- Identification of clinician and IPC manager with authority to approve or halt construction activities under defined conditions.

- Power requirements for future expansions and installations.

- Emerging healthcare technologies.

- Space for removal and refitting of equipment.

- Materials of construction for recycling potential and disposal.

- Toxicity and environmental impact of gases, paints and polymers.

- Specific healthcare services risks (IPC, etc).

- Occupational Health and Safety Regulations and requirements.

19. A risk assessment shall consider the following aspects:

- Identification of occupancy groups which are susceptible to risks.

- Identification of building services, such as ventilation, in the proximity of the construction activity and the potential impact on function. Specific consideration should be given to specialist ventilation systems.

- Need for supplementary protection or support systems for building services.

- Impact on fire-protection and -response systems, and action plans.

- Impact of noise and vibration on occupants and equipment.

20. Opportunistic environmental or airborne microorganisms and allergens, which are liberated or distributed during retrofitting and decommissioning activities, can present a significant hazard to patients and employees unusually at risk. Where the environmental and risk assessments identify the need for intervention or mitigating controls, the following shall be considered:

- Establishment of rigid non-permeable barriers between patients or staff and construction activities during construction, with the inclusion of appropriate “airlocks” where traffic between occupied and construction areas is required.

- Increased ventilation rates and ventilation efficiency to areas at risk.

- Extraction and filtration systems serving the construction area. Where there is a chance of re-entrainment of diluted exhausted air, a minimum of an EN779-F9 filter should be installed as the final filtration stage. Where air is actively re-circulated it should be filtered with at least an EN1822-H13 final filter.

- Establishment of a protective pressure cascade or airflow direction between zones.

21. For further guidance on the decommissioning of health facilities, the Health Decommissioning and Disposal of Health Facilities and Health Technology guidance document should be referred to.

Sustainability & Environmental Measures

Design Life cycle

Sustainability in designs for new health facilities can be addressed through the following steps:

22. Target setting: Challenging but realistic sustainability targets should be set for the building and agreed with all of the key stakeholders of the project, including the design team, the facilities manager and the funder or owner of the building. Targets should take into account government policy and strategies, as well as local and international best practice.

23. Design principles: Strategies and design principles required to achieve these sustainability objectives should be understood and established from the outset. For instance, energy targets may require passive environmental control strategies to be well understood and established from the outset. These strategies and their implications can be understood through an analysis of best-practice examples and precedents.

24. Integrated design: Once targets and design principles have been established, an integrated design process should be used to ensure that all aspects of the building work together to achieve the required performance. This requires different disciplines to work closely together.

25. Testing: Throughout the design process, checks should be carried out to ensure that the targets set will be achieved. This can be done through calculations, modelling and analysis which assesses performance against targets set. Where aspects of the design are found not to meet targets, a re-evaluation of the design should be carried out and, in an iterative and integrated way, improved to ensure that the performance achieves, or surpasses, targets set.

26. Detailed design and implementation: It is important to ensure that the design principles set out are carried out in detail, or this may affect operational performance. This includes, for instance, seemingly insignificant details such as appropriate locations for switches, labels and instructions.

27. Handover: On completion, effective processes should be followed to ensure that design intentions are carried through into building operation. This includes effective commissioning, handover and training processes which ensure that designers, subcontractors and suppliers transfer knowledge and skills to facilities managers to ensure effective management of the building.

28. Refer to Sustainability Guide for further information on sustainability.

PART - DESIGN SPECIFICATIONS

Design considerations

Best engineering practices for the design, specification, testing and management of wet services, vacuum, medical gases, building electrical, electronic, and lighting and ventilation systems are contained in this guide. This guide also defines applicable local and international informative standards and describes regulatory aspects for consideration.

Heating Ventilation and Air-conditioning

Airborne-Precaution Risk Classification for Healthcare Zones

South Africa does not have a uniform formal policy regarding the classification and design of infection prevention and control zones. Provision of multi-bed patient accommodation and internal waiting areas for out-patients is common practice in South Africa.

| Patient/Staff Susceptibility to Infection** | ||||

|---|---|---|---|---|

| Low | Moderate | High | ||

| Potential for cross infection* | High |

|

|

|

| Moderate |

|

|

| |

| Low |

|

|

controls

| |

For this reason, a burden is placed on the building services design to ensure that the utilities and services provided do not hinder efforts to manage airborne-infection control

The matrix presented above is proposed for consideration when planning mechanical building ventilation for airborne IPC.

Table 24.5 gives further guidance on ventilation rates for specific areas.

For further information regarding the requirements for airborne-infection precaution rooms, refer to Part C, Section 23.3 of this document and the Infection Prevention and Control.

An alternative exposure-based model can be considered where infection risk can be quantified in terms of the environmental reproductive number.

Ventilation requirements

Natural ventilation

Due to the high capital outlay required, medical facilities in countries defined as developing, such as South Africa, are generally not provided with “traditional” engineering control measures, such as ventilation, to achieve acceptable environmental management. -Dr S A Parsons, 2002

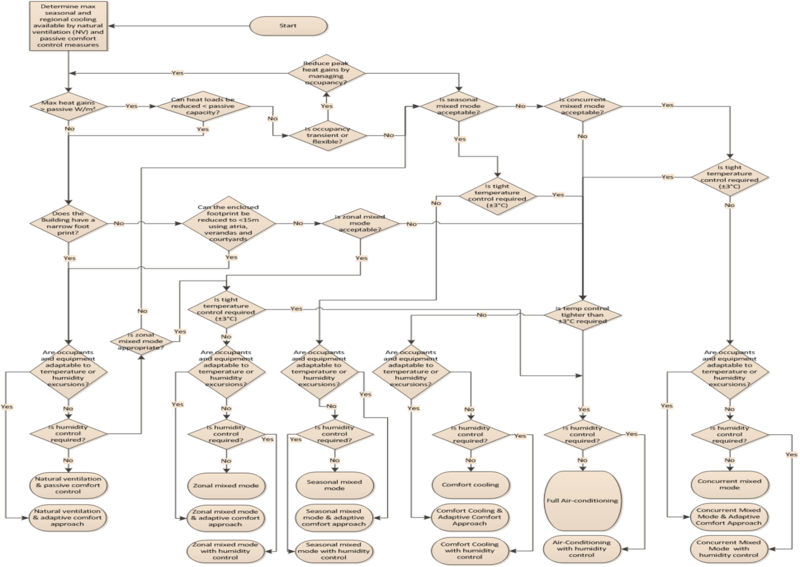

- Natural ventilation is driven by a combination of thermo convective or buoyancy effects and wind pressure. Since the drivers of Natural ventilation are inherently variable, natural ventilation has a high variability in effectiveness.

2. In addition to the variability of the drivers of natural ventilation, the responses of the occupants of a space could have a negative impact on the variability of the ventilation system’s performance by opening and closing windows and doors. For this reason it is recommended that, where natural ventilation is considered as the primary ventilation mode, dedicated and controllable ventilation openings be designed and created in the building

3. For additional design guidance on natural ventilation design, the CIBSE Applications Manual AM10 or similar can be consulted.

4. Peak and minimum internal temperatures should be calculated or modelled thermally for a space, for summer and wintertime respectively.

5. The design parameters for internal spaces should be found in the detailed room requirement sheets published in the individual IUSS guidance documents of the various functional units. Where these room requirement sheets are absent or lacking adequate information, the data contained in this document may be used.

6. The following design interventions should be considered for implementation, singly or in combination, in the following hierarchy where the internal design condition cannot be met:

- Reducing solar and internal heat gains

- Using thermal mass to move room temperature extremes to outside of occupancy periods.

- Change occupancy schedules seasonally to improve indoor comfort conditions. (eg. Shift consultation hours from or towards the warmest daytime hours during summer or winter respectively)

- Introducing passive cooling or heating strategies

- Increasing ventilation rates

- Providing mechanical cooling or heating

7. Where natural ventilation alone cannot achieve the required air quality, quantity and consistency, mixed mode ventilation shall be considered as a solution preferred over full mechanical ventilation.

8. Mixed mode ventilation is considered as an assisted type of natural ventilation. Here fans are used in combination with damper controlled ventilation openings to ensure minimum ventilation rates are achieved.

9. Where mixed mode ventilation cannot achieve the required air quality, quantity or consistency, mechanical ventilation may be considered as a solution.

Mechanical ventilation and air-conditioning

10. Where the quantity and quality of air within a space can be maintained to a satisfactory degree of consistency, natural ventilation should always be the preferred solution.

11. The design parameters for internal spaces should be found in the detailed room-requirement sheets published in the individual IUSS guidance documents of the various functional units.Where these room-requirement sheets are absent or lacking adequate information, the data contained in this document may be used.

12. Temperature, Relative Humidity (RH) and fresh air requirements

- The adaptive approach to thermal comfort will result in designs with broader acceptable temperature ranges and thereby greater energy efficiency[1]. The following aspects have been found to influence the perception of thermal comfort in a space

- Climate and social custom

- Rate of temperature drift >1°C daily and 3°C weekly

- Exponentially time-weighted mean outdoor temperatures

- For the majority of occupied spaces, unless otherwise indicated, a temperature range of 18-28°C is acceptable, although the level of gowning of the patients and staff needs to be considered in the design

- Clinical practices seldom use explosive anaesthetic gases and the requirement for humidity control from this perspective is generally outdated. Direct humidity control is only required in a select few specialised areas. In general, humidity control is indirect, but the designer should consider the resultant humidity levels and the impact on comfort levels in the space.

Table 3: Specialist ventilation systems, provides a list of spaces that have particular temperature and humidity requirements that are critical to the effective provision of healthcare.

This page or section needs to be cleaned up. |

13. Zoning of a building

13.1. Where the choice between a central and a local ventilation plant needs to be made, the following points should be considered:

- Fire compartmentalization

- Air-handling unit (AHU) sizing

- Duct sizing

- Occupancy schedules

- Occupancy activity levels

- Building, environmental and equipment heat loads

- Airborne contamination control

- Tenancy, functional unit or utility metering

13.2. Zoning of ventilation systems has a large impact on ventilation efficiency and effectiveness.

14. Minimum fresh air requirements

- For minimum fresh air requirements refer to the National Building Regulations and relevant IUSS Infrastructure Guidance Document. Where any apparent conflict between the functional requirements and the “deemed to satisfy” guidance emerges, the rational design route to regulatory compliance would need to be followed so as not to compromise any system’s functionality.

- Where odour control is a consideration, a ventilation rate of 10 litres per second per person may be used.

- Where airborne cross infection is controlled primarily through dilution and natural ventilation, medium and high risk areas require 60 or 160 litres per second per person respectively.

- Where airborne cross infection is controlled primarily through dilution and forced ventilation, medium and high risk areas require 60 or 80 litres per second per person respectively.

15. Ventilation rates

- Air change rates per hour (AC/h) are specified in this document for a room with ceiling height of 3m. Where ceiling heights are increased these rates can be reduced, and vice versa.

- Minimum ventilation rates quoted as air changes per hour should be complied with together with the recommended rate of fresh air per occupant

16. Supply-only vs balanced ventilation systems

- Supply-only ventilation systems do not supply air to all spaces individually, but instead supply air to only the least contaminated or most critical space. Air is then allowed to cascade from the “clean” core to adjacent and auxiliary spaces. Where this type of system is employed, it is critical to be aware of and control the risk of contamination generated in the clean core and permeating through the entire system. This type of system is not appropriate for thoracic and sepsis theatres or areas where unpleasant or noxious odours, fumes and vapours may be generated. It is also important to ensure and prove that the statutory conditions for ventilation and fresh air rates are met for all spaces.

17. Airborne contamination-control concepts

- Airborne contamination control often requires the application of one or more of the concepts described below since airborne contaminants can be generated both internally and external to the controlled zone.

17.2. Barrier concept

- The barrier concept relies on airtight enclosures to isolate the contamination source. Typical examples are glove boxes or barrier isolators.

17.3. Aerodynamic effects

- The displacement concept relies on flushing contaminants away with high volumes of air at relatively low velocity.

- The dilution concept involves reducing contamination levels in a space by diluting them with quantities of "clean" air. The ventilation rate required is a function of the required contamination level, the rate of generation of contaminants in the space, and the ventilation efficiency.

- The pressure-differential concept relies on the pressure differential developed between spaces when "clean" air cascades through small orifices, such as door gaps and pressure-control dampers. The pressure differential, and resulting airflow developed, prevents contaminants from moving into higher pressure “clean” areas from lower pressure "dirty" areas. The following diagram gives indicative values for infiltration and exfiltration rates associated with varying pressure differentials (Pa) and opening sizes (m²).

17.4. Where ventilation rates and fresh air proportions are described within these guidance documents they are to serve as guidance values only. It is the responsibility of the designer to ensure that the ventilation rate selected is appropriate for the specific zone’s operational conditions, occupancy, contamination rates, pressurization, leakage rates, ventilation efficiency and external ambient conditions to achieve the desired airborne contamination and bio-burden levels. Ventilation rates higher or lower than the guidance values may achieve the desired conditions.

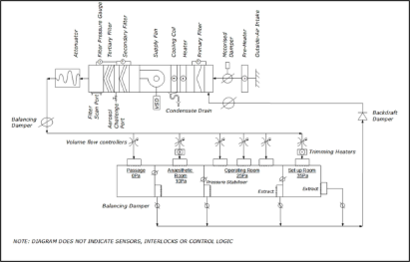

18. AIR HANDLING UNITS AND FANS

18.1. GENERAL

- AHUs and fans shall be protected from adverse weather and wind sources which may upset their performance or reliability.

- A detailed name plate shall be included on the air handling units with manufacturer, design air volume, fan speed, cooling capacity, filter data and heating capacity.

- The air handling unit shall include individual differential pressure gauges over each installed filter bank. The gauges shall measure the pressure differential between upstream and downstream of the filter banks. The filter designation and design filter change pressure shall be neatly and clearly marked on each gauge.

- Air-handling units functioning in an airborne contamination control system, and demanding prescribed airflow rates, shall be provided with an electronic control system including variable frequency controllers with direct fan drives to automatically maintain design airflow for all filter conditions. The fans and drives will be selected to maintain design flow rates with all filters at maximum rated pressures.

- Where a ventilation system performs a critical role, air handling units shall have separate electrical distribution boards (Essential and Non-essential). The fan will be on essential power and heater elements may be on non-essential power.

- All compartment doors on the air handling unit shall be clearly labelled

- Where systems require duplicate standby fans or air-handling units these shall be installed with backdraught dampers, sufficiently air-tight for the application (eg EN1751 Cat 3 or 4). Special design and control consideration shall be given to limiting the build-up and dwelling of contaminants in the standby unit.

- AHU’s should be placed in easily accessible plant rooms with sufficient space for maintenance. Access stairs to the plant rooms should permit a technician to easily carry replacement parts or a toolbox into the plant.AHU’s located in ceiling voids are not appropriate or conducive to good operational management.

- AHUs should be designed for a working life of 20 - 25 years

- AHUs shall be designed and positioned such that the largest components, including heating and cooling coils, can be removed and replaced.

- AHUs greater than 1m wide should have hinged access doors large enough to provide full entry. Doors shall be unlockable and openable from the inside of the unit.

- Fan and filter plenums shall be provided with internal illumination and viewing portals such that internal components can be visually inspected without stopping or opening the unit.

- AHUs shall be designed such that dry steam humidification devices can be retrofitted into the systems with minimal disruption and without compromising its performance.

- Ventilation components shall have a drainage or condensate pumping system if they can produce moisture. Drip trays shall be of a corrosion resistant material and drainage systems shall have a 1:20 fall away from the unit in all directions. The unit shall have its own drain trap which shall be sized such that it can function at the fan's full static pressure. The first 3 meters of a dedicated condensate drainage line shall be insulated to prevent condensation within the plantroom. Where a condensate drain services a negative pressure plenum, clear air gaps of 15mm or anti-backflow devices are recommended at the trap discharge into the drainage system.

- Drop stop eliminators in stainless steel frames shall be employed, if fin spacing is less than 10 fins per inch, after the cooling coils in areas with high humidity levels. This includes all coastal areas for off coil temperatures of 10° and less

- In full fresh air systems, primary filters may be situated at the fresh air intake opening of the air-handling unit only if the climate does not require anti-fog or de-icing coils.

- Cooling or heating coils will be protected by a pleated primary filter, rated in accordance with SANS 1424, as minimum.

- In recirculation air systems, primary filters will be situated after the fresh/return air mixing plenum. This arrangement will ensure that blinding filters don’t inhibit the prescribed fresh air proportion.

- The final stage of filters on units serving operating theatres must be located after the supply fan chamber to filter any debris that might come from the fan chamber. HEPA filters should be protected from this potential dust and debris.

18.2. AIR EXTRACTION SYSTEMS

- The design of exhaust systems shall take special consideration of the potential for re-entrainment of contaminated exhaust air into air intakes through, inter alia, openable windows. Where this potential exists, precautionary measures such as aerosol or chemical filtration of exhaust should be applied, as appropriate.

- Single ablution facilities serving private wards or staff do not require extract ventilation, provided there are windows openable to outside.

- Extract ventilation shall be provided by either ceiling extract grilles connected to an in-line ducted fan with outside discharge air grilles by means of galvanized mild steel or PVC tubular ducting or odour extraction system.

- Extract grilles may be of the PVC type with adjustable disc valves, or powder coated or anodized aluminium type with adjustable dampers.

- All multiple toilets shall be provided with ventilation systems, which will serve as an extract ventilation system.

- Single toilet facilities serving private wards for staff do not require extract ventilation, provided there are windows openable to outside

- Where it is not considered safe to enter a space without respiratory protection, the air exhausted from that space should be rendered safe through filtration, decontamination or dilution before discharge.

- The design of exhaust system from airborne precaution areas should be such that all components can be safely maintained during normal service and safely disposed of at decommissioning.

- Planning for disposal of contaminated filters should be as for all biohazardous material.

- Filtration and decontamination components shall be installed upstream of fans, monitoring and control devices.

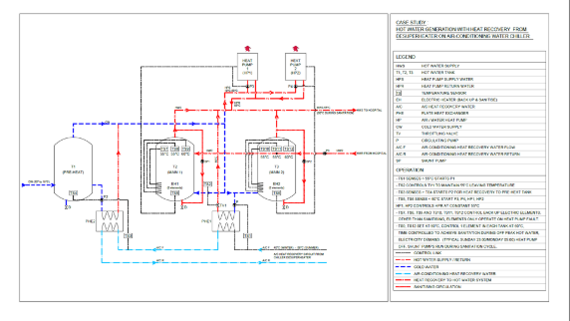

18.3. ENERGY RECOVERY SYSTEMS

1.3.1. Where full or partial exhaust is required for ventilation systems, energy recovery technologies should be considered. Enthalpy wheels offer a high level of efficiency but introduce a risk of cross infection as the wheel is exposed to both the exhaust and supply airstreams. An enthalpy or energy recovery wheel may only be used if pressure and filtration measures are taken to ensure it is not a potential source of cross infection or re-infection. Energy recovery wheels incorporating purge sections have a markedly reduced efficiency and are not considered to provide sufficient protection against biological cross contamination. Where cross infection is a considered risk, the following conditions shall be met.

- The exhaust airstream shall be consistently maintained at a lower static pressure than that of the supply airstream.

- The exhaust air shall be filtered with aerosol filters upstream of the energy recovery device.

- Levels of filtration, redundancy and safety shall meet the requirements of the biological pathogenicity class in consideration.

19. FILTRATION

- With the exception of the few specialist areas with aero-biological requirements, the primary purpose of filtration is to protect ventilated spaces and ventilation equipment from dust build-up.

- When designing filtration systems serving spaces with a high airborne cross contamination risk, consideration should be given to the safety of maintenance staff that may be required to handle contaminated filters. Where any safety risk is present, contaminated filters should be installed in safe-change or decontaminatable housings.

- All ventilation filter banks should be installed with a means of visually checking the filter pressure across them in Pascals (Pa)

- Filters are classified as being General Fine or Aerosol filters and are to be specified in accordance with the SANS 1424, EN779 or EN1822.

- General filters are selected to remove particles large enough to block cooling and heater fins and settle out of the airstream into the air distribution system. General filters are graded in terms of their “synthetic dust weight arrestance”. General filter grading ranges from G1 to G4. G3 and G4 filters are appropriate for primary air intake and tempered air supply respectively. General filters are not appropriate for combating airborne cross-contamination control.

- Fine filters are selected to keep a ventilated space visibly clean and for the protection of HEPA filters. Fine filters are graded in terms of their “Dust Spot Efficiency” from M5 to F9. F9 filters are capable of arresting particles with the approximate size of some bacteria and can be used for low level cleanrooms (ISO 14644-1 Class 8).

- Aerosol filters are selected for their efficiency in arresting sub-micron particles. They are graded in accordance with their “Most Penetrating Particle Size” (MPPS). Aerosol filters are subdivided into three categories: Efficient Particulate Air (EPA) and High Efficiency Particulate Air (HEPA) and Ultra high Particulate Air (ULPA) Filters in accordance with the EN1822:2009. The table below describes the classification of aerosol filters by integral and local values as defined in the EN1822. SULPA filters are not discussed within this document.

| Group | Filter Class

EN1822 |

Integral Value | Local Value |

| Efficiency % | Efficiency % | ||

| EPA | E10 | 85% | - |

| E11 | 95% | - | |

| E12 | 99.5% | - | |

| HEPA | H13 | 99.95% | 99.75% |

| H14 | 99.995% | 99.975% | |

| ULPA | U15 | 99.9995% | 99.9975% |

| U16 | 99.99995% | 99.99975% | |

| U17 | 99.999995% | 99.999975% |

8. HEPA filter installations shall include both an upstream challenge aerosol injection port and a downstream scan port to facilitate filter challenge testing. ULPA filter installations shall be designed such that an agreed upon test method can be accomplished.

9. All filters used for airborne precaution rooms, theatres or other areas with a high airborne contamination risk shall be selected with a construction suitable for incineration. These filters shall not contain PVC.

10. The installation and testing of HEPA filters shall only be conducted by suitably qualified technicians.

11. HEPA filters shall be specified to be compliant with the requirements of EN1822. Each HEPA filter is to be supplied with an individual factory test certificate displaying that filter's serial number, MPPS rating and DOP arrestance rating.

12. Type-test certificates are only acceptable for EPA and not HEPA filters.

20. HEAT REJECTION EQUIPMENT.

20.1. The location of heat rejection equipment shall be planned such that it does not adversely affect the performance, maintenance or reliability of any related or unrelated equipment, or pose an avoidable health risk.

20.2. The use of evaporative cooling towers shall only be considered where:

- Space, system capacity or efficiency demands their use.

- An effective plan for the control of legionella must be developed and implemented.

21. AIR DISTRIBUTION SYSTEMS

- Discharge from extraction systems shall be located such that contaminated air does not get drawn into any system's air intake of get re-entrained though openable windows.

- The use of internally insulated ducting is not appropriate as internal linings will perish and slough off with aging. Particles from duct linings contaminate final filters and ducting components.

- Flexible ductwork is unsuitable for air distribution in healthcare applications. It should only be used for the final connection to an air terminal and then kept to less than 1.0m. Bends in flexible ductwork should be avoided.

- The use of dampers to throttle a deliberate oversupply of airflow should be avoided. Balance by design is preferable although this will not necessarily reduce the total fan pressure. Use of adjustable blade dampers should be kept to a minimum as these items may drift, can be tampered with and increase the complexity of commissioning. The use of constant volume dampers may improve stability of volume critical systems but may also mask inefficient design and be the source of increased system noise.

- Cleaning and access doors are to be installed in all air distribution ductwork to facilitate:

- Cleaning

- Inspection

- Measurement

- Maintenance

21.6. Ductwork installations shall be designed, built, installed and commissioned in accordance with SANS 1238: Air-conditioning ductwork and SANS 10173: The installation, testing and balancing of air-conditioning ductwork

22. ELECTRONIC CONTROLS

- Location of sensors in ventilation systems should ensure that the temperature and humidity measurement for monitoring control is representative of the occupied area

- The humidifier control will include humidity monitoring of the mixed airstream downstream of the humidifier lance and shall prevent this airstream from approaching dew point.

- The use of variable speed drives (VSD) can save energy in systems operating under varying motor loads. Reducing the fan speed when filters are new or clean can result in considerable energy savings over the life of a system. Reliability of smaller sized VSDs is a potential drawback, and for this reason VSDs must be selected and sized for high service life. VSDs should also be installed such they can be bypassed and the system can be run in manual control while failed VSDs are replaced or repaired. When designing with variable speed drives, cognisance should be taken of a motor’s minimum cooling requirements and the maximum restart rate. Caution should be exercised where variable speed drives are used in conjunction with constant volume dampers or volume flow controllers. This combination could drive up total system pressure where duct total pressure as opposed to velocity pressure is used as control feedback. Additional requirements for the selection of drives for variable air volume (VAV) fans is described in SAN204:2011

- Plant control systems should incorporate start-up and shut-down sequencing logic to prevent flow reversals and overheating.

- Set-back controls should be considered for spaces that have intermittent occupancy. This feature should be used with caution in specialist areas as poorly considered set-back conditions could compromise containment or contamination control.

- Where more than one ventilation system serves a department, system interlocks may be required to prevent unwanted airflow reversals during system shutdown or failure.

- Operational status indicators should be displayed locally in areas served by ventilation systems.

- "Low Air Flow" and "Plant Failure" alarms should also be installed in a location which can be manned by relevant and trained staff.

- Electronic control systems should be developed using recognised open protocols and standards such as BACnet DeviceNet, LonWorks, Modbus, SOAP and XML.

23. SPECIALIST VENTILATION SYSTEMS

23.1. The following areas will require specialist ventilation systems:

Table 3 Specialist Ventilation Systems

| Department Name | Ventilation system type |

| Operating departments | Clean and Ultra clean ventilation systems: ISO8 to ISO5 & UDAF |

| Obstetrics | Clean ventilation systems ISO8 |

| High care, Critical Care and Intensive Care | Fine filtered ventilation or Clean ventilation systems: Unclassified - ISO8 |

| Isolation units | Negative pressure ventilation, no recirculation |

| Pathology labs | Biosafety ventilation: (BSL2 – BSL4) |

| IVF Labs | Clean ventilation systems: VOC Filtration |

| Burns units | Clean ventilation systems/ Negative pressure ventilation/ RH control |

| Neonatal Units | Dedicated ventilation systems/ RH control |

| Mortuary unit | Cold Rooms/ Extraction systems/ Odour Control |

23.2. Broad requirements for these systems are in this document. The engineering team shall consult each department’s specific design guidance document for detailed requirements.

23.3. AIRBORNE PRECAUTION ROOMS (INCLUDING TB)

- Where specific diseases are considered in the design of an airborne precaution room, the US CDC's "Select Agent List" may be consulted for design guidance until a South African list is compiled.

- Airborne precaution rooms shall be ventilated with a minimum of 12AC/h of fresh air or uncontaminated air. High risk areas such as sputum booths and airborne diseases wards shall have a nominal ventilation rate of 80 ℓ/s per person..

- Medium Risk areas such as congregate spaces such as waiting areas shall have a nominal ventilation rate of 60ℓ/s per person.

- Mechanical ventilation may be employed to achieve the minimum ventilation rates. It should be noted that very high ventilation rates can be achieved by employing a well-considered natural ventilation design. Consideration may also be given to mixed mode ventilation systems, which combine mechanical and passive ventilation and temperature control. An open window policy may therefore be adopted, with careful consideration of all the associated cross infection risks and management challenges.

- Airborne precaution rooms shall be designed so as to provide thermal comfort. Where occupants have freedom in location and dress code, an adaptive thermal comfort model should be adopted. Heating, cooling and energy recovery devices shall pose no risk of harbouring pathogens or increasing the cross-infection risk.

- Air from the airborne precaution rooms shall not flow into adjacent, uncontaminated rooms or adjacent airborne precaution rooms. Air shall not flow from a room with a higher airborne infection risk category to a room with a lower risk category.

- Ventilation ducting and pipe work shall not form a conduit by which pathogens can transfer from one zone to another whether the ventilation system is running or not. Filtration devices and anti-backflow devices may be employed provided these do not pose a risk of infection to maintenance staff.

- Filtration requirements for supply and exhaust air should follow the bio-containment requirements of that select agent being contained.

- The location of supply and air terminals should be such that the airflow patterns generated within the room serve to suppress and remove airborne particles.

- For general waiting areas or where the pathogens are known and unlikely to pose an environmental risk, exhaust air filtration may not be required provided exhausted air is directed 3m away from open-able windows and air intakes and there is no risk of re-entrainment of this air. See section 18.2.

- Commissioning and validation shall be well planned, diligently executed, fully documented and approved by suitably experienced professionals. It is advisable to have the validation process conducted or approved by a party independent of the designer and installer.

- Numerical or physical modelling may be of value in the design and validation process.

23.4. OPERATING THEATRE VENTILATION DESIGN

23.4.1. GENERAL REQUIREMENTS

- Constant volume systems shall be employed to maintain the correct pressure with respect to any adjoining rooms. The contamination control concept shall be developed in accordance with ISO14644-4

- Temperature range shall generally be 18°C to 24°C with a minimum relative humidity of 45% unless otherwise specified

- A pressure differential of 10-15Pa is to be maintained between the theatre and adjacent rooms when all doors are closed.

- Theatres may be maintained at a room pressure positive or negative to the adjacent rooms depending on the contamination control requirements.

- A theatre’s room pressure shall always be positive relative to technical spaces.

- Negative pressure theatres should not employ recirculation of room air.

- Minimum fresh air requirements are 5-7 Air Changes per hour to satisfy the occupancy requirements.

- Additional fresh air may be required for pressurisation and shall be designed to maintain the required pressure differential between the theatre, the ancillary rooms and the corridors. The fresh air rate shall be selected to offer the required pressurisation at the greatest possible energy efficiency. Rules of thumb rates of percentage fresh air as a function of the supply air rate are not acceptable methods for determining additional fresh air requirements for pressurization.

- Separate temperature controls in each theatre are to be provided.

- No manual on and off switching of air handling plant to be done from within the theatres.

- Automatic motion sensors / thermal sensors to ensure that the units are switched on when there is a presence in the theatre. Theatre ventilation switching may be linked to the theatre unit’s lights.

- Automatic switching of ventilation system to incorporate run-on timers to prevent overheating and accidental shutdown.

- An additional override to be used to switch the units on when the temperature in the theatre exceeds 25°C for the protection of stored medicine

- For ISO7 and cleaner areas, HEPA filters shall be mounted within the supply air terminals and UDAF plenums.

- These validation tests shall be performed in accordance with SANS 14644Parts 1, 2 and 3 at the recommended intervals (SANS 14644-2) or after any system or building intervention has been completed. Detail records are to be kept and be presented upon demand.

- No internal ducting insulation is permitted.

- In multi theatre suites it is advisable to have dedicated AHUs per theatre. [TR1]

23.4.2. UNIDIRECTIONAL AIRFLOW OR ULTRACLEAN THEATRES

- Airborne particulate contamination levels are not to exceed ISO 14644-1 Class 5 under protected zones (UDAF and Setup area) and ISO 14644-1 Class 6 in background and ancillary areas. These conditions are to be achieved under operational conditions.

- Temperature range shall generally be 18°C to 24°C and relative humidity 45% to 60% unless otherwise specified

- Ultra-clean theatre ventilation shall not be completely shut down when unoccupied unless required for maintenance interventions. Ventilation systems serving UDAF plenums shall instead switch to a minimum velocity set-back mode to prevent contaminants settling underneath the UDAF screens.

- Delivery of the conditioned air shall be by downward movement from the ceiling to four low level exhaust outlets located near the corners.

- All ductwork between HEPA filter housings and air terminals shall be high pressure rated and constructed of galvanised sheet metal. In the final connection to the terminal, where alignment necessitates, a maximum of 300mm of thermally insulated, high pressure flexible ducting may be used.

- The Air Conditioning system is to be complete with G4 primary, F9 secondary and H13 HEPA Filters.

- The ventilation systems shall be designed with a mean air velocity of between 0.35 & 0.45 m/sec measured below the UDAF screen and at the working height.

- Refer to ISO14644-4 for guideline ventilation rates for balance of areas.

- The mean velocities below the UDAF screen and at the working height shall not differ by more than ±10%

- A standard size of the UDAF screen is 2400 x 2400mm. The required size could vary dependent on the layout and function of the operating theatre.

- The protected zone below the UDAF plenum shall be clearly demarcated on the floor

23.4.3 CLEAN OR MAJOR THEATRES

- Airborne particulate contamination levels are not to exceed ISO 14644-1 Class 6 in all protected areas and Class 7 in background areas. These conditions are to be demonstrated as achievable under operational conditions.

- The ventilation system is to include G4 Primary, F9 Secondary and final H13 HEPA filters. No air tempering and conditioning equipment is permitted downstream of the HEPA filters

- The conditioned air is to be introduced into the theatre via suitable diffusers.

- Refer to ISO14644-4 for guideline ventilation rates.

- Additional fresh air may be required for pressurization and shall be designed to maintain the required pressure differential between the theatre, the ancillary rooms and the corridors. The fresh air rate shall be selected to offer the required pressurization at the greatest possible energy efficiency.

- These validation tests shall be performed in accordance with SANS 14644 Parts 1, 2 and 3 at the recommended intervals (ISO14644-2) or after any system or building intervention has been completed. Detail records are to be kept and be presented upon demand.

- All ductwork between the HEPA filter housing and the air terminal shall be of rigid medium pressure ducting (SANS 10173) construction. All ductwork upstream of the HEPA filter housing shall be rigid high-pressure ducting. Where alignment necessitates, the final connection to the terminal shall have a maximum of 300mm of thermally insulated flexible ducting.

- Recirculation from the theatre room to zones outside of the theatre room is not permitted and all recirculated air shall be filtered through the secondard and HEPA filters as a minimum. Recirculation from zones outside of any theatre room into that theatre room is not permitted.

23.4.4. MINOR THEATRES

- Airborne particulate contamination levels are not to exceed ISO 14644-1 Class 8 in all areas. These conditions are to be achieved under operational conditions.

- For recirculation systems the ventilation system is to include G4 Primary, F9 Secondary and H13 HEPA filters.

- For single pass systems the ventilation system is to include G4 Primary and F9 Secondary filters.

- The conditioned air is to be introduced into the theatre via suitably sized diffusers.

- Refer to ISO14644-4 for guideline ventilation rates.

- All ductwork between the HEPA filter housing and the air terminal shall be of rigid medium pressure ducting (SANS 10173) construction. All ductwork upstream of the HEPA filter housing shall be rigid high pressure ducting. Where alignment necessitates, the final connection to the terminal shall have a maximum of 300mm of thermally insulated flexible ducting.

- For ISO7 and cleaner areas, HEPA filters shall be mounted within the supply air terminals and UDAF plenums.

VALIDATION OF SPECIALIST VENTILATION SYSTEMS

- Validation testing shall be completed in accordance with national standards for standardized tests (eg ISO14644 and ISO 14698 for cleanrooms) and shall be completed against mutually agreed protocols for non-standard tests.

- It essential that the validation testing of a ventilation system’s contamination control performance parameters is conducted against operational, and not only "at-rest", conditions. Validation against "as-built" conditions offers little insight into the ultimate performance of the system.

- Pre-Commissioning Checks shall cover the following aspects prior to the commencement of formal commissioning:

- Check whether the Design Specification satisfactorily addresses the demands of the User Requirement Specification.

- Check whether the ventilation systems have been provided and installed in accordance with the design specifications and drawings

- Check that the buildings either housing or served by the ventilation equipment is complete and finished such that testing can commence safely and effectively.

- Check that all AHUs, chillers, heat rejection equipment and filters are sufficiently accessible for inspection and maintenance.

- All components are connected and are functional

- Door gaps and openings are installed and sized as specified in specialised zones

- Airflow control devices are installed in the correct locations and in the correct orientation

- Duct and filter tests ports are installed and sealed satisfactorily

- Safety and control interlocks are established

- Fan and drive guards are in place

- Safety and warning signs are in place

- All major system components or sub-systems are clearly labelled with functional or controls identification in a neat and durable fashion.

- Fluid and air pressure monitoring gauges are labelled with identification and acceptable maximum and minimum operating conditions.

- All wiring, piping and ducting colour banding is complete in accordance with SANS-1091

- CLEANLINESS CHECKS:

- AHUs shall be checked for cleanliness on internal plenums with special attention being paid to fan and discharge plenums and condensate drip trays and drain lines.

- Ducting serving “clean” areas shall be cleaned prior to installation and the ends shall be sealed until installation. Open ends of duct runs shall similarly remain sealed during construction. Spot checks for compliance during the installation process are recommended.

- Recommended Filtration Levels and Ventilation Rates for Mechanically Ventilated Areas

This table serves as a quick reference guide and will be revised as and when detailed room data sheets are developed within each department’s guidance documents.

| Systems Serving[TvR1] : | Primary

Filters |

Secondary

Filters |

Secondary

Filters |

Tertiary

Filters |

Airflow Type | Airborne Particle Count | Ventilation[1]

(Considering Forced) |

Temperature | ||

| Pleated Panel | Pleated Panel/ Bag | High Capacity

Rigid Minipleat |

High Capacity

Rigid Minipleat |

Unidirectional/

Turbulent/ Mixed |

Protected zone | Background area | Minimum

Outdoor Air |

Min. Air changes

per Hour |

Design Range[2] | |

| EN779 Classification

G4 |

EN779 Classification

F6 |

EN779 Classification

F9 |

EN1822 Classification

H13-H14 |

U/T/M | SANS14644-1

Class |

SANS14644-1

Class |

ℓ/s per person | (Assuming 3m ceiling height) | °C | |

| Casualty/Minor Stitch Procedure room | X | X | T | 7.5 | 20 | |||||

| Theatres: Maternity/Caesarean | X | X | X** | T | NA | 7 | 7.5 | 20 | ||

| Theatres: General Surgery | X | X | X** | T | NA | 7 | 7.5 | 20 | ||

| Theatres: Gynaecology | X | X | X** | T | NA | 7 | 7.5 | 20 | ||

| Theatres: Ophthalmology | X | X | X** | T | NA | 7 | 7.5 | 20 | ||

| Theatres: Urology | X | X | X** | T | NA | 7 | 10 | 20 | ||

| Theatres: Endoscopy | X | X | X** | T | NA | 7 | 80 | 20 | ||

| Theatres: Plastic Surgery | X | X | X | T | 6 | 7 | 7.5 | 70*** | ||

| Theatres: Bone Surgery/Orthopaedic | X | X | X | M | 5 | 7 | 7.5 | 70 | ||

| Theatres: Thoracic | X | X | X | M | 5 | 7 | 80 | 70 | ||

| Theatres: Vascular??? | X | X | X | M | 5 | 7 | 7.5 | 70 | ||

| Theatres: Neuro Surgery | X | X | X | M | 5 | 7 | 7.5 | 70 | ||

| Waiting and Congregate Areas | X | 60 | 8 | 18-28 | ||||||

| Auditoriums | X | 7.5 | 4 | 22-26 | ||||||

| Mortuary | X | X | 12 | 22-25 | ||||||

| Bath Room | 25 | 10 | N/A | |||||||

| Dirty Utility Room | 40 | 10 | N/A | |||||||

| Blood Bank | X | 4 | 22-25 | |||||||

| Casualty | X | X | 7.5 | 12 | 22-25 | |||||

| CSSD | X | X | X | 7.5 | 20 | 22-25 | ||||

| Dark Room | X | 10 | 22-25 | |||||||

| Dining Rooms/Canteens | X | 7.5 | 10 | 18-28 | ||||||

| General Stores | X | 4 | N/A | |||||||

| Laboratories | X | X | 6 | 22-24[3] | ||||||

| Labour/Delivery Room | X | 4 | 22-24 | |||||||

| Laundry – General | X | 7.5 | 10 | N/A | ||||||

| Lecture Halls | X | 7.5 | 4 | 22-26 | ||||||

| Outpatients Departments | X | 60 | 4 | 18-28 | ||||||

| Pharmacy Dispensing | X | X | 7.5 | 4 | 22-24 | |||||

| Pharmacy Store | X | X | 7.5 | 4 | 22-24 | |||||

| Specialist Clinics- ENT | X | X | 7.5 | 4 | 22-26 | |||||

| Sterilizer Equipment | X | 7.5 | 10 | N/A | ||||||

| Toilet Room | 7.5 | 10 | N/A | |||||||

| Units: Treatment Room | X | 7.5 | 6 | 24-26 | ||||||

| Units: Burns | X | X | X | T | 8 | 8 | 7.5 | 20 | 26-28

(50-60%RH) | |

| Units: HCU / CCU | X | X | 7.5 | 30 | 22-24 | |||||

| Units: ICU | X | X | 7.5 | 30 | 22-24 | |||||

| Units: ICU Neonatal | X | X | 7.5 | 6 | 26-28 | |||||

| Wards: General | X | 7.5 | 4 | 18-28 | ||||||

| Wards: Airborne Precaution Rooms/Isolation[4] | X | X | 80 | 12 | 22-24 | |||||

| Wards: Maternity | X | 7.5 | 4 | 24-26 | ||||||

| Wards: Medical | X | 7.5 | 4 | 24-26 | ||||||

| Wards: Paediatric | X | 7.5 | 4 | 22-25 | ||||||

| Wards: Psychiatric | X | 7.5 | 4 | 20-28 | ||||||

| Wards: Orthopaedic | X | 7.5 | 4 | 20-28 | ||||||

| Wards: Surgical | X | X | 7.5 | 4 | 20-28 | |||||

| Wards: TB | X | 80 | 12 | 20-28 | ||||||

| Radiology: General | X | X | 7.5 | 6 | 22-24 | |||||

| Radiology: Airborne Precaution | X | X | 60 | 6 | 22-24 | |||||

| Radiology: MR/CT

Scanner |

60 | 6 | 2-24 | |||||||

[1] These rates are considered for forced ventilation systems only. Average natural ventilation rates may be higher

[2] Temperature range not to be exceeded for more than 50 hours per year.

[3] Specialist cleanrooms and laboratories may require lower temperatures.

[4] Levels of filtration are dependent on pathogenicity. Exhaust filtration may also be required.

Commissioning tests shall include and record, but not be limited to:

| System | Commissioning Test | Special Instructions |

| All | Standard of installation | Test to be authorised by client's representative. |

| Air Handling Units and Fans | Fan motor drive speed and rotation. | Cognisance should be taken of motor cooling requirements |

| Fan motor current draw. | - | |

| HEPA Filter challenge testing. | In accordance with ISO DIS 14644-3 | |

| AHU heating and cooling coil performance | Report on-coil and off-coil air conditions for full heating and full cooling with no air bypass. | |

| AHU leakage tests | - | |

| Heating and Chilled Water circuits have been charged, dosed and pressure tested | - | |

| Flow rates and pressures across heat exchangers, pumps and compressors | Pressure drops and flow rates should be measured, recorded and confirmed to be in accordance with design specifications. | |

| Room conditions | Airflow and room pressure balancing in accordance with design tolerances. | In accordance with ISO DIS 14644-3 Acceptance criteria Normally +10-0% |

| Room Temperature and humidity | - | |

| Air Distribution systems | Dampers and registers shall be locked and marked after balancing | - |

| Duct leakage tests for medium and high pressure ducting in accordance with SANS 10173 or DW/143 requirements, as agreed upon | - | |

| Water Distribution Systems | Pressure Drops and Flow Rates | Pressure drops and flow rates should be measured, recorded and confirmed to be in accordance with design specifications. |

| Control System | Control system loop and function checks | - |

| Alarm Checks | - | |

| System Start/Stop sequencing checks | - | |

| System Set-Back mode checks | Include room condition and contiguous system impacts |

24.7. Select validation tests shall be conducted at intervals defined by the client:

| Tests | Required/ Optional | Recommended Frequency of testing | At-Rest or In-Operation Testing |

| Airflow volume tests | Required | 12 months | At-Rest |

| Airflow visualization

(Airborne precaution rooms) |

Required | 12 Months | At-Rest & In-Operation |

| UDAF Velocity Tests | Required | 12 Months | At-Rest & In-Operation |

| UDAF Airflow Visualisation | Required | 6 Months | At-Rest & In-Operation |

| Room pressure tests | Optional | 3 Months | At-Rest & In-Operation |

| Airflow direction tests | Required | 1 Month | At-Rest & In-Operation |

| Discreet practice counts | Required | 12 Months | In-Operation |

| Bio-burden testing | Required | 1 Month | At-Rest |

| Filter challenge testing | Optional/Recommended | 24 Months | At-Rest |

| Room Condition recovery | Required | 24 Months | In Operation |

24.8. Prescribed validation reports shall include:

- References to the test protocol

- Acceptance criteria

- Test results

- Test equipment identification and calibration status

- Name and signature of tester

- Name and signature of facility representative

- Dates of test and acceptance by client

Medical gas installations

25. The design parameters for internal spaces should be found in the detailed room requirement sheets published in the individual IUSS guidance documents of the various functional units. Where these room requirement sheets are absent or lacking adequate information, the data contained in this document may be used.

26. All units of a health establishment, except sub-acute and hospice facilities, where patients are accommodated and treated, must have medial gases and vacuum provided by medical grade piped services, with indexed terminal connecter points. Bottle systems may be provided in sub-acute and outpatient facilities.

27. Mobile gas services must be available for crisis situations.

28. Sub-acute facilities must have one mobile oxygen cylinder per 10 patients and one suction machine for every 10 patients.

29. The minimum services to be supplied to all Acute Care areas are described in Table 11.1. Should the data in this table be in conflict be the table presented in the individual departmental design guidance documents, those individual guidance documents take precedence.

| Description | Oxygen | HP Air | LP Air | N2O | VAC | Scavenging | |

|---|---|---|---|---|---|---|---|

| Major Theatre8 | Theatre Panel | 1 | 1 | 1 | 1 | 2 | |

| Per Pendant | 2 | 2 | 2 | 1 | 2 | 1 | |

| Minor Theatre8 | Theatre Panel | 1 | 1 | 1 | 1 | 2 | |

| Per Pendant | 2 | 2 | 2 | 1 | 2 | 1 | |

| Cath Lab8 | Theatre Panel | 1 | 1 | 1 | 1 | 2 | |

| Per Pendant | 1 | 1 | 1 | 1 | |||

| Post Op | Bedhead

Trunking |

1 | 1 | 1 | |||

| Procedure

Room |

Theatre Panel | 1 | 1 | 2 | |||

| Resuscitation Bay | 1 | 1 | 2 | ||||

| Delivery Room | 2 | 1 | 2 | ||||

| High Care Unit, Per Bed | 1 | 1 | 2 | ||||

| Intensive Care Unit Per Bed | 2 | 2 | 2 | ||||

| Casualty Per Bed | 1 | 1 | 1 | ||||

| Wards | 1 per

2 beds |

1 per

2 beds |

30. A gas alarm system to monitor gases, excluding scavenging, must be installed in a location that is manned 24 hours per day. A slave panel must also be installed in the intensive care unit and in the theatre complex. This alarm system must be connected to UPS.

31. All piped vacuum and oxygen systems must have mobile back-up systems with adequately trained staff to handle them. . The back-up service shall be automatically activated if the line pressure drops below the set operating pressure. All back-up services and change-over valves shall be on UPS and diesel generator supplies.

32. Medical air (low pressure) for respiratory purposes must be provided at a fixed pipeline pressure of 400 kPa. Medical air (high pressure) for driving surgical power tools must be provided at a terminal usage pressure between 70 0kPa and 1000 kPa, depending on the tools/equipment to be used. ICU and operating rooms must be provided with a back-up system for both low and high pressure service. Air compressors must be fed off standby power supply.

33. Anaesthetic gas scavenging, which is a low-pressure suction system that removes exhaled anaesthetic gases from the patient circuit must be provided. Each outlet point must have its own balancing valve to allow the system to be balanced progressively from the furthest outlet point towards the suction fan or pump.

34. The vacuum installation shall comply with SANS 7396-1. Vacuum liquid bottle traps must be installed to collect any blood/fluid etc. that may be drawn into the pipeline. One bottle trap per operating room, ICU, ward block and other patient unit, must be supplied. Where possible the vacuum trap should be located in a sluice room. Emergency suction facilities must be provided in the ICU and High Care, operating rooms, recovery room, delivery room, emergency unit and nursery, and must be available to all patient rooms. Bacteria filters must be installed in the vacuum main before the vacuum reservoir and pumps. Used filters are considered a bio-hazard and must be handled accordingly when being changed and disposed. Care must be given to the location of the exhaust discharge of vacuum plants taking into account locations of windows and other air inlet points. Vacuum pumps must be fed off standby power supply.

35. Gas service isolation valves should be carefully positioned for each clinical unit to avoid shutdowns of major sections.

36. Gas service outlets to be identified and colour-coded with 3mm lettering.

37. Should compressed air operated autoclaves be employed, High Pressure medical air may be taken to such equipment, provided the system possesses sufficient capacity.

38. Should pendants requiring compressed air for aid of movement be employed, High Pressure Medical Air may be taken to them, provided the system possesses sufficient capacity.

39. Should Health Technology Workshops require medical gas outlets for testing and servicing of medical equipment, the required service may be taken to them, provided the system possesses sufficient capacity.

40. SANS 7396-1, as amended, specifies the requirements from design to commissioning of medical gas and vacuum systems

41. Medical gas and vacuum pipelines shall be marked in accordance with SANS 7396-1 and ISO 5359 as applicable

42. SANS 7396-2, as amended, specifies the requirements from design to commissioning of anaesthetic gas scavenging disposal systems.

43. Colour coding of anaesthetic gas scavenging disposal system shall be red magenta or in accordance with the national standard. An example of red magenta is 3050-R40B, in accordance with SS 01 91 02.(Refer to SANS 73962-2).

44. Colour coding of non-medical gas piping must be as per SANS 10140-3:2003.

45. SANS 1409, as amended, specifies the requirements for non-interchangeable outlet sockets and probes for specific medical (gas and vacuum) services used in hospitals.

46. Plain ended copper tubing for low pressure medical gas and vacuum shall comply with the requirements of SANS 1453 and SANS 1067-1 or SANS 1067-2, as deemed suitable.

47. Laboratory gas taps and valves shall be marked as described in SANS 10140-4

Electrical installations

48. Lighting in Hospitals

48.1. The design parameters for internal spaces should be found in the detailed room requirement sheets published in the individual IUSS guidance documents of the various functional units. Where these room requirement sheets are absent or lacking adequate information, the data contained in this document may be used.

48.2. Within the available scope presented in the National Building Regulations, the following lighting requirements should be interpreted with the aim of maximum energy and cost efficiency. The following innovations could be adopted to achieve this aim:

- Daylight harvesting with passive building elements and active systems response.

- Adoption of task lighting, where appropriate, within the scope of present and future planned activities.

- Considered selection of lighting elements and solutions.

- Considered selection of internal colours and materials.

- Accommodation for visually impaired occupants.

48.3. Where a requirement for natural light (daylight) is stated, this may be met if the room opens onto an atrium or courtyard, or if a roof light is incorporated, provided that privacy within the room or space is maintained. In addition, daylight may be borrowed from an adjacent room by means of glazing the wall in between, provided that the adjacent room or corridor is within the same unit.

48.4. Save where otherwise provided for in the requirements, health establishments must comply with the following: (Adapted from CIBSE Lighting Guide 2: Hospitals and Healthcare settings).

Table 6 Levels of Indoor Lighting (Adapted from CIBSE Lighting Guide 2: Hospitals and Healthcare settings)

| Area, unit or department | Service illuminance

/ lux |

Max. point illuminance/ lux

(not to be exceeded) |

Unified

Glare Rating (UGR) |

Min.Ra | Measurement

Point |

Type of control | Standby lighting level (%) |

| Common areas